Modified Bitumen

Modified Bitumen roof systems are asphalt-based and provide superior waterproofing characteristics. The typical lifespan for these systems is about 10 to 20 years. Modified Bitumen roofs are usually installed as a two ply system and are always fully-adhered. They are made up of asphalt that has been modified with a polymer to create plastic or rubber-like properties. The modifiers provide increased resistance to brittleness, cold temperatures, and provide increased elasticity and strength.

The most common modifiers are APP (Atactic Polypropylene) and SBS (Styrene Butadiene Styrene). APP modifier, when added, provides a plasticized quality to the asphalt. By adding 30% APP, the asphalt can be stretched up to 50% of its original length. The APP modified asphalt is reinforced with a polyester mat and manufactured into a roll product. These membranes have extra asphalt on the back side, which allows it to bond to the substrate through applications such as heat-welded or torch-applied methods.

- Torch Applied – The APP modified membrane is applied with the use of an open flame torch to melt the bottom side of the sheet.

- Heat Welding – The welder is used to blow out hot air, which fuses the back side of the membrane to the substrate during application. This method is a safer alternative than torch applied, as it is less of a fire hazard.

SBS modifier, when combined with asphalt, produces rubberized properties. By adding 10%-15% SBS to the asphalt, it is able to be stretched 6 times its normal length, and then can return to its original size once relaxed. This helps deal with the stresses of normal expansion and contraction of a roof. Reinforcements for SBS modified asphalt include fiberglass, polyester, or a combination of both. These membranes are most commonly applied with hot asphalt or cold adhesive. There are also self-adhering SBS membranes, which contains an adhesive backing.

- Hot Asphalt Application – Hot asphalt is applied to the felts or substrate with the use of a machine, or is physically mopped down before the membrane is laid over the hot asphalt. The hot asphalt acts as the adhesive and allows the membrane to bond to the substrate.

- Cold Adhesive – The modified membrane is set in a cold process using specially-formulated, asphalt-based adhesives as it is being applied.

- Self Adhered – The bottom surface of the membrane is covered with an adhesive and release paper. Once the paper is removed, the adhesive allows the membrane to adhere to the substrate without the use of additional adhesives.

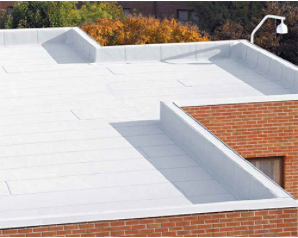

There are numerous surfacing options for APP and SBS-modified roofs, including factory-applied mineral surfaces, gravel surfaces, smooth surfaces, and “cool roof” coatings, which are highly reflective coatings that can help save on cooling costs.

Residential Locations We Serve:

Kentucky

Chrestwood

Goshen

Jefferson Town

LaGrange

Louisville

Mount Washington

Prospect

Simpsonville

Shelbyville

Saint Matthews

Indiana

Charlestown

Clarksville

Corydon

Floyds Knobs

Jeffersonville

New Albany

Sellersburg

Texas

San Marcos

South Austin

Southeast Austin

Dripping Springs

Wimberley

Driftwood

Blanco

Johnson City

Buda

New Braunfels

Selma

Seguin

Lockhart