Single Ply Membrane

Single ply roofing membranes (sometimes referred to as TPO, PVC, or EPDM) have grown in popularity over the past 30 years for use on commercial buildings, thanks to their flexibility, relative ease of installation, and competitive price.

Single Ply roofing is composed of four basic elements:

- An insulation layer

- A single ply membrane usually made of plastic or rubber

- Flashing

- An adhesive that melds the layers together

Perhaps the single greatest advantage to single ply roofing is its energy savings. With a proper coating, the light-colored roof surface reflects heat and offers a significant reduction in energy use.

Tests show that the surface temperature of a white roof rises only 4 degrees Fahrenheit on a sunny, 85-degree day, while on a black or dark colored roof the temperature rises 42 degrees under the same conditions. Over time, the reflectivity can translate into significant energy savings!

Three main types of single ply

- TPO (thermoplastic polyolefin) — TPO roofing systems offer a fire-resistant membrane with polyester reinforcement to strengthen the bond. The membrane is also resistant to chemical, grease, and punctures, making it a good alternative for rooftop areas with high traffic.

- PVC (poly-vinyl chloride) — PVC formulation allows for added long-term flexibility of the membrane, making it extremely durable and impact resistant. PVC is pliable with excellent weathering characteristics and resistance to harsh chemicals and industrial pollutants.

- EPDM (ethylene propylene diene monomer rubber) — EPDM has the appearance and feel of an inner tube, and it rebounds when stretched. It is a highly-durable roofing material and can last in excess of 40 years.

In addition to the energy savings, single ply roofing has other advantages:

- Durable: Single ply is impact resistant, and it also resists tough challenges like intense UV rays, high winds, thermal shocks and chemical residue. It is especially suited for roofs that are exposed to concentrations of grease and oil.

- Lightweight: The thin layers in single ply roofing make it lightweight and easy to install.

- Flexible: Single ply roofing materials can accommodate unconventional roof designs.

- Life Expectancy: A properly installed single ply roofing membrane can last up to 40 years.

- Inexpensive: Thanks to ease of installation (no heavy equipment and it can be applied during wet weather) single ply is quick to install, saving on both material and labor costs.

- Retardant: The layers and adhesive help eliminate the danger of fire and smoke pollution.

Single ply roofs are low maintenance:

The bonding of the layers makes single ply roofs incredibly durable as well as impact resistant. Its ability to ward off environmental challenges like UV rays, winds and chemicals, means single ply roof repair is rare, and that single ply roof maintenance is minimal.

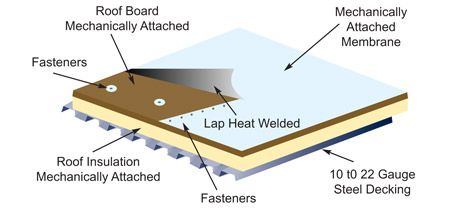

There are three standard application methods for TPO and PVC roofing:

- Fully Adhered – A system that requires using a solvent or water-based adhesive to adhere the rubber to the substrate or insulation board.

- Mechanically Fastened – This method is done by attaching the membrane to the deck using mechanical fasteners along each loose edge of the material.

- Loose Laid / Ballasted – An application done by fastening the perimeter of the membrane, and then the roof is covered with gravel to secure the loose laid sections into place.